Industrial Design

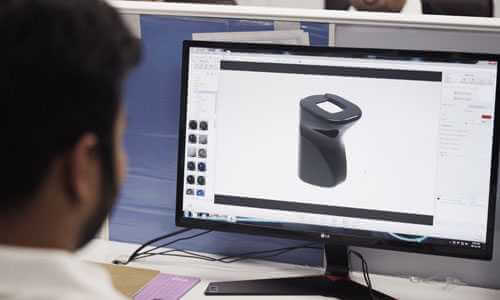

Concept design is the starting point of any product development process. Using everything, from sketches, 3D renderings, foam models, to other appropriate techniques; we develop multiple conceptual approaches based on the product requirements.

We endeavor to provide as many ideas as possible in the available time frame. Companies with in-house design teams find this concept generation service very useful. It offers clients alternatives developed from an external perspective, in addition to those generated by the company's own unit. This approach results in a larger pool of ideas from which to select.

Our Industrial Designs Include

Concept Design

CFM options

Photo realistic renderings

Design Strategy Consulting

Product Mock-ups

Engineering Design

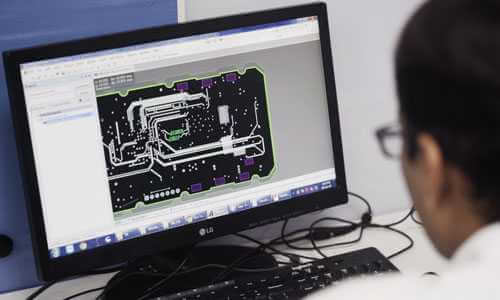

Every component is accurately modelled in 3D using the leading CAD software. All parts and assemblies are subjected to interface analysis, draft analysis, thickness analysis and tolerance analysis utilising virtual analytics tools.

Also, designs are evaluated from the thermal and structural point of views, as well as other relevant safety parameters, to forecast the longevity and reliability of the product. This leads to design optimization and cost efficiencies in manufacturing and assembly.

Comprehensive documentation clearly specifies the material, it's finishing, tolerance, and dimensions. Our detailed engineering design service gives clients the necessary confidence to proceed with the mass production because the optimal material, efficient manufacturing, and cost-effective processes are identified in advance.

Our Engineering Design Include

Detailed part design and CAD modelling

DFM, DFA

Material Selection and Analysis

Process Feasibility

Analysis of thermal and Stress conditions

UI Design

We have developed an integrated user interface (UI) solutions for a suite of products ranging from medical devices, set-top boxes to information kiosks. Our solutions are user centric, and we aim to meet the needs of the users in an intuitive and easy-to-use manner.

To do this, we gather all the necessary information and group it by functionality and dependency. Using flow charts and storyboarding, we break down the data into layers of embedded information and hotkeys, etc. Smart layouts, graphics, icons, and colour schemes are incorporated to bring the UI to life, making it available to the user in whatever form (or on whatever device) they prefer to use.

Tooling Development

We have considerable experience in organizing and dealing with product manufacturing - both locally and offshore. We have developed a reliable network of High Quality Chinese and Indian manufacturers, as the sources for plastics, sheet metal, and rubber parts.

We liaise with these suppliers and check their DFM reports, then with mould analysis advise them on material and process selection to ensure that parts are fabricated righteously in the very first time.

We also manage the Organization and manufacturing of parts, whether that involves small batches or mass production.

Our Tooling Development Include

Injection moulding

Blow moulds

Tooling strategy

Vacuum forming tools

Fiberglass moulds

Tool design analysis and consulting

Tooling coordination

Prototyping

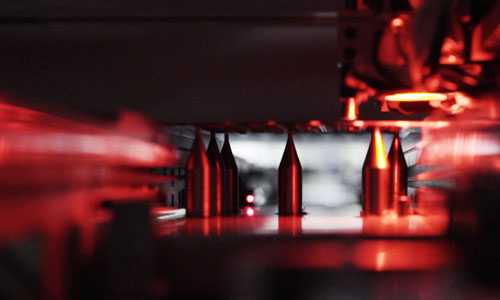

Prototyping gives us the opportunity to get a clear view of aesthetics, as well as allowing physical appearance to get a vivid sense of its strength and size. Prototypes are essential for understanding the ergonomic aspects of any product.

We utilise advanced rapid prototyping techniques such as Stereo lithography Apparatus (SLA), Selective Laser Sintering (SLS), and Computer Numerical Control (CNC) machining to produce accurate prototypes, whether for aesthetic evaluation, fit and function testing, or solely for design verification. Also, we create early evaluation mock-ups using foam, POP foam, and Styrofoam and Ciba wood.

Over the years, we have developed an excellent network of vendors in India, China, and Taiwan that executes quality prototypes at reasonable costs.

Our Prototyping Include

Visual Appearance Models

Handcrafted Models

Functional Prototypes

Foam Mock-Ups

CNC machined Prototypes, Silicone moulds and Vacuum Casted parts

Batch Production

Our design team works closely with factory production personnel to educate, train, and build the product to the highest standards. This way, we ensure our clients have fewer doubts and headaches about production issues and the product teething process.

We work closely with the designated suppliers to help them create the parts of the specification, for each one as laid out in the CFM charts. Our engineers check every part and approve each one for the production. We also train the quality assessment staff on how to identify defects and to follow the correct assembly procedure so that the right pieces are used and can be kept together error-free. We have a vast experience in the production and are fully conversant with mass production techniques and issues.